The FDY spinning production line is a vital piece of machinery used in the textile industry to produce Fully Drawn Yarn (FDY). FDY is known for its high strength and smooth texture, making it suitable for a wide variety of applications, from garments to industrial textiles. The FDY spinning production line works by processing synthetic fibers, such as PET (Polyester), PA (Polyamide), and PP (Polypropylene), into finished yarns through a combination of extrusion, drawing, and winding processes.

The FDY spinning production line is designed to convert synthetic polymers, such as PET, PA, and PP, into high-quality yarns. This process involves several stages:

Extrusion of Polymer: The raw polymer is melted and extruded through a spinneret to form filaments.

Drawing: The filaments are then drawn to increase their strength and elongation.

Texturing (Optional): Depending on the end product requirements, some FDY lines incorporate texturing to give the yarn a desired texture or appearance.

Winding: Finally, the yarn is wound onto spools for further processing or direct use in weaving and knitting.

The key advantage of an FDY spinning production line is its ability to produce yarns with consistent quality and performance, making them ideal for applications that demand durability and smoothness, such as in the production of high-performance fabrics.

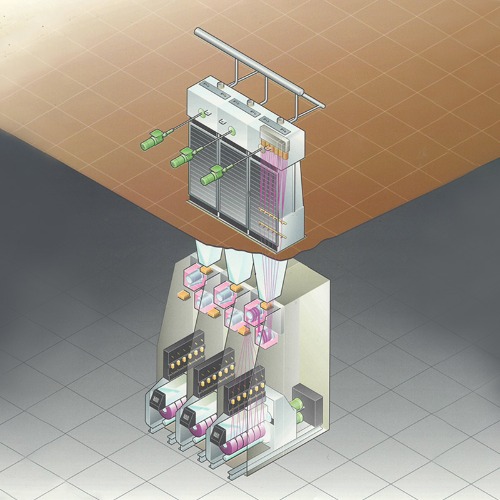

An FDY spinning production line consists of several critical components that work together to transform raw materials into high-quality yarns. These include:

The operational process of an FDY spinning production line can be divided into the following stages:

Melt Polymerization: Raw polymer material such as PET, PA, or PP is first melted in the extruder, where it reaches a molten state for easy extrusion.

Extrusion: The molten polymer is then forced through the spinneret to form continuous filaments. The size of the holes in the spinneret controls the diameter of the filaments.

Cooling and Drawing: After extrusion, the filaments are cooled and then drawn to the desired thickness and strength. The drawing process involves stretching the filament by a set percentage, which imparts the necessary properties like tensile strength and elongation.

Texturing (Optional): Some FDY lines incorporate a texturing step where the filaments are treated to produce textured yarns with added crimp, elasticity, or other unique features. This process is typically used for applications like fabrics requiring stretch or textured effects.

Winding and Packaging: The final step involves winding the drawn and textured yarn onto cones or spools. The winding speed and tension are carefully controlled to ensure uniformity in the final product.

FDY spinning production lines offer several advantages over traditional spinning methods:

FDY yarns produced from FDY spinning production lines are used in a wide range of applications. These include:

| Component | Function | Materials Processed |

|---|---|---|

| Polymer Extruder | Melts and extrudes raw polymer into filaments | PET, PA, PP, and other polymers |

| Spinneret | Forms filaments through small holes | PET, PA, PP, and other polymers |

| Drawing Machine | Stretches filaments to increase strength and elongation | PET, PA, PP, and other polymers |

| Texturing Unit | Adds texture, curl, or crimp to the yarn | PET, PA, PP, and other polymers (optional) |

| Winding Machine | Winds yarn onto spools or cones for storage and shipping | All types of FDY yarns |

The FDY spinning production line is a crucial piece of equipment in the textile industry, enabling the production of high-quality yarns with excellent strength, smoothness, and durability. By understanding its operation and the components involved, manufacturers can optimize production, reduce costs, and improve product quality.

1. What is the FDY spinning production line used for?

The FDY spinning production line is used to produce Fully Drawn Yarn (FDY) from synthetic polymers like PET, PA, and PP. The yarn produced is used in various industries, including fashion, home textiles, and industrial fabrics.

2. What materials can be processed in an FDY spinning production line?

FDY spinning production lines can process polymers like PET, PA, PP, and other synthetic fibers into high-quality yarns.

3. What is the role of the drawing machine in the FDY spinning production line?

The drawing machine stretches the filaments to increase their strength and elongation, enhancing the yarn’s final properties.

4. Can FDY yarns be used in industrial applications?

Yes, FDY yarns are highly durable and can be used in industrial fabrics, including geotextiles, automotive textiles, and filtration materials.

5. What are the main benefits of using an FDY spinning production line?

The main benefits include high efficiency, consistent quality, versatility in processing different materials, and energy efficiency.