In the fast-evolving textile industry, manufacturers constantly strive for higher productivity, better quality, and cost-effective operations. Among the most crucial components of polyester yarn manufacturing is the POY spinning machine. This advanced machinery has transformed the polyester yarn production process by enhancing efficiency and optimizing resource use.

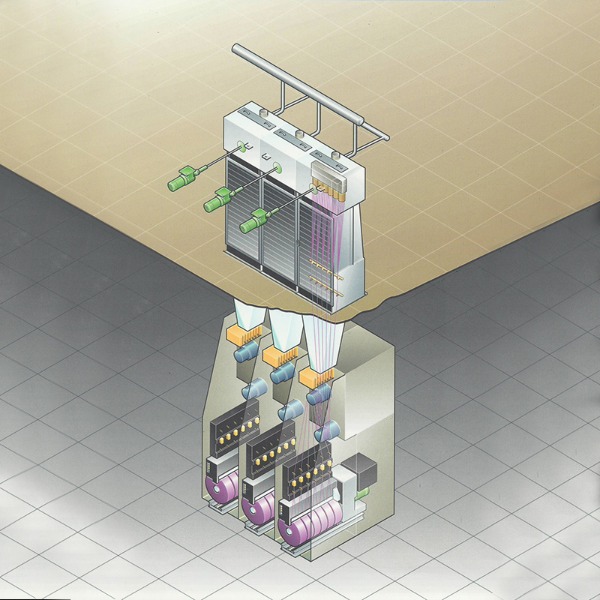

A POY spinning machine is a specialized textile machine used to produce partially oriented yarn (POY) from polyester fibers. This yarn is a key raw material in the production of various types of fabrics, including those used in the apparel, home textiles, and industrial sectors. The POY spinning process involves the extrusion of polyester chips, followed by spinning, drawing, and winding. These machines are designed to provide a high level of automation, speed, and precision in producing yarns with desired properties.

The POY spinning machine is part of the broader POY spinning production line, which encompasses several interconnected processes such as fiber preparation, spinning, drawing, and packaging. Each step in the production line is designed to maximize efficiency and minimize waste, making the entire process faster and more cost-effective.

The primary advantage of a POY spinning machine lies in its ability to produce large quantities of yarn in a shorter time frame. Modern machines are capable of operating at high speeds, ensuring faster production rates. By optimizing the spinning and drawing processes, the machines can significantly reduce cycle times while maintaining consistent yarn quality.

The POY spinning production line incorporates several automatic features that reduce the need for manual labor, further enhancing overall productivity. This not only boosts output but also reduces the risk of human errors, improving the overall reliability of the production process.

The precision of the POY spinning machine ensures that the yarn produced is of consistent quality. This includes uniform thickness, strength, and elasticity, which are crucial factors for the performance of polyester fabrics. The advanced controls and monitoring systems of modern spinning machines enable manufacturers to maintain high standards of yarn quality throughout the production process.

A consistent yarn quality reduces the likelihood of defects during further processing steps such as dyeing, weaving, and knitting. This leads to fewer rejections and waste, ultimately lowering the cost per unit of finished fabric.

Another significant advantage of using a POY spinning machine is its energy efficiency. Modern spinning machines are equipped with energy-saving features such as variable speed drives, energy-efficient motors, and improved heat management systems. These innovations help reduce energy consumption, making the production process more sustainable.

In addition to reducing the environmental impact, lower energy consumption also leads to cost savings for manufacturers, which can be reinvested in other areas of the business.

The POY spinning machine offers a high degree of customization in terms of yarn properties. Manufacturers can adjust various parameters, such as fiber tension, draw ratio, and spinning speed, to produce yarns that meet specific requirements. Whether it’s for creating high-strength yarns, finer threads, or multi-component yarns, the POY spinning production line allows for a versatile production process.

This flexibility is particularly useful for businesses that need to produce a wide range of yarns for different fabric applications, giving them a competitive edge in the market.

For many manufacturers, purchasing new machinery may not always be financially feasible. In such cases, second-hand POY spinning machines can be an attractive option. These machines often come at a fraction of the price of new ones, making them an affordable choice for small and medium-sized enterprises (SMEs).

Second-hand POY spinning machines can still provide excellent performance, especially when they have been well-maintained and refurbished. These machines offer a cost-effective way to expand production capacity without the hefty investment required for new machines. However, it’s essential to verify the condition and reliability of used machines to ensure they meet the desired quality standards.

Below is a summary of the key features and capabilities of a modern POY spinning machine:

| Feature | Description |

|---|---|

| High-Speed Spinning | Capable of operating at speeds up to 2000 meters per minute for faster production. |

| Energy-Efficient Motors | Reduced power consumption while maintaining high output levels. |

| Automated Control Systems | Advanced sensors and controls for consistent yarn quality and reduced defects. |

| Adjustable Draw Ratios | Enables the production of yarns with varying thickness and strength. |

| Multi-Component Yarn Production | Can produce complex yarn structures for specialized applications. |

| Low Maintenance Requirements | Designed for minimal downtime and easy maintenance to maximize uptime. |

Proper maintenance is critical to ensuring that the POY spinning machine continues to operate at peak efficiency. Regular cleaning, oiling, and inspection of the machine’s components help prevent breakdowns and extend the life of the equipment. Additionally, keeping up with the machine’s calibration and ensuring that parts such as the hot godet and balancing machine are functioning correctly is essential to maintaining yarn quality.

Jiaxing Shengbang Mechanical Equipment Co., Ltd. provide comprehensive support services, including machine maintenance, parts replacement, and technical consultation. Jiaxing Shengbang is a leading company specializing in the development, production, sales, and maintenance of spinning machines and key components. The company also focuses on the R&D of new materials and fabrics. Their production facilities are equipped with advanced machinery, including CNC machine tools, plasma-coating equipment, and temperature calibration tools from renowned manufacturers. The company’s R&D capabilities allow them to develop revolutionary multi-purpose spinning test machines that can easily produce a wide range of yarns, including POY, FDY, and bicomponent yarns.

1. What is the difference between POY and FDY yarn?

POY (Partially Oriented Yarn) is a semi-finished yarn that requires further processing, while FDY (Fully Drawn Yarn) is ready for use in fabric production. POY yarn is more flexible and can be further drawn to achieve desired strength.

2. Can a second-hand POY spinning machine offer the same performance as a new one?

Yes, provided the machine has been well-maintained, refurbished, and meets the required quality standards. A second-hand POY spinning machine can be a cost-effective alternative to purchasing new equipment.

3. How can I improve the efficiency of my POY spinning machine?

Regular maintenance, optimizing machine settings, and ensuring that components such as the hot godet are calibrated correctly can improve machine efficiency.

4. What are the benefits of using a POY spinning production line?

A POY spinning production line integrates multiple processes into one streamlined system, improving productivity, consistency, and reducing manual labor and waste.

5. Are there specific industries that benefit the most from POY spinning machines?

POY spinning machines are widely used in the textile, apparel, and industrial fabric industries for producing yarns that meet specific strength, elasticity, and finish requirements.

The POY spinning machine has revolutionized polyester yarn manufacturing by improving productivity, enhancing yarn quality, reducing energy consumption, and offering versatile production options. Whether you’re considering purchasing new machinery or exploring second-hand POY spinning machines, understanding their benefits and key features can help streamline your production process and give you a competitive edge in the market.