In the vast ecosystem of industrial manufacturing, some machines operate quietly at the margins, far from the spotlight. Extruders, reactors, looms, and presses often dominate attention, but without equally critical end-of-line equipment, entire production systems would falter. Among these unsung heroes, the Take up winder stands out as one of the most vital.

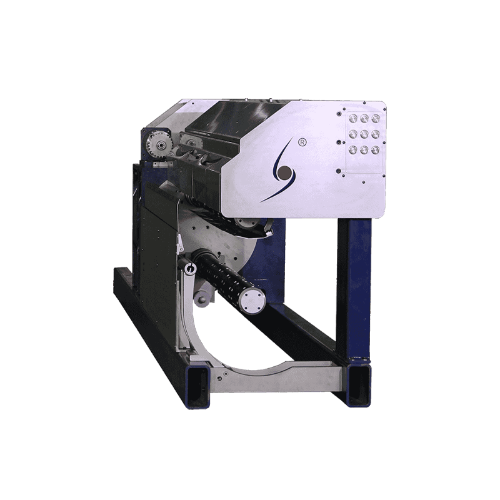

At its core, a Take up winder performs the deceptively simple task of winding continuous strands, sheets, or filaments of material onto a spool, reel, or core. Whether the material is a delicate polymer film, a tough steel wire, a synthetic textile filament, or a long sheet of coated paper, the winder ensures that it is collected neatly, compactly, and consistently. This transformation of linear flow into a stable roll is essential for storage, transport, and all subsequent processing.

The concept of winding is deeply embedded in human history. Ancient rope makers and weavers used rudimentary hand cranks and wooden rollers to gather yarns or cords. Yet as industrialization accelerated, the need for precise, automated, and high-speed winding technology became urgent. The modern Take up winder, with its tension control systems, advanced drive motors, and automated roll exchange functions, represents the culmination of centuries of innovation.

In many industries, the Take up winder is the final checkpoint in a continuous production line. Without it, defects such as slack rolls, crushed cores, or tangled spools could compromise entire batches of output. Downtime would multiply, and material waste could spiral into unacceptable levels. This report takes a deep dive into the world of take-up winders: their classification, design, applications, advantages, and future directions.

Surface Driven Winders

These winders apply rotational force via a surface-contacting drum or roller that drives the outer layer of the winding roll. They are widely used for robust materials such as paper, films, foils, and fabrics. Their greatest strength lies in creating compact, high-density rolls with excellent uniformity. However, excessive surface pressure can sometimes deform fragile cores.

Center Driven Winders

Instead of external contact, these winders apply torque directly to the core or arbor itself. This allows highly precise control of winding tension, making them indispensable for delicate materials such as thin plastic films, fine wires, or specialty fibers. The technical challenge arises as roll diameter increases—constant adjustments are necessary to maintain stable torque and tension.

Spindle Driven Winders

A variation of center drive, spindle-driven winders rotate the spindle or bobbin directly. They are tailored for yarns, threads, and small-diameter rolls where precision and compactness are paramount.

Automatic Winders

Fully automated winders integrate sensors and control systems that manage every function, from core loading and cutting to package doffing and roll labeling. They enable true continuous production and are standard in high-output facilities.

Manual Winders

These rely heavily on operator involvement for spool loading, tension adjustment, and roll removal. While less efficient, they are valuable in low-volume, customized, or laboratory environments where flexibility matters more than speed.

Constant Tension Winders

Equipped with advanced feedback loops, these maintain consistent tension regardless of speed or roll diameter. They are essential for preventing stretching or breakage in sensitive materials like films, optical fibers, and specialty laminates.

Variable Tension Winders

Here, tension is deliberately adjusted throughout the winding process. This accommodates materials that require gentler handling at startup but can withstand higher forces as the roll grows.

Traverse Winders

By moving the strand laterally as it winds, traverse systems ensure even layering across the core. This is especially important for wire, cable, and filament products, where improper layering could cause catastrophic tangling.

Every Take up winder is a system of interdependent components engineered for precise performance.

The universality of winding makes Take up winder technology indispensable across industries.

In fiber production, winders collect freshly extruded monofilaments or multifilament bundles onto bobbins. Proper tension ensures downstream processes—such as weaving, knitting, and dyeing—proceed without yarn breakage.

After drawing or insulation extrusion, wires and cables must be wound into reels or drums. The Take up winder not only prevents tangling but also ensures that heavy reels remain stable for shipping.

For plastic sheets, packaging films, and laminates, winding quality is directly tied to visual and functional quality. Wrinkles or uneven rolls could render entire production runs unusable. Here, sophisticated tension and surface-driven systems dominate.

Printing presses, coating machines, and lamination lines all end with winders that collect sheets into master rolls. Consistent tension is crucial to guarantee rolls that can later be unwound for cutting or converting.

From nonwoven medical fabrics and filtration membranes to fiberglass for insulation and carbon fiber tows for composites, the Take up winder quietly enables countless modern products.

| Type | Drive Method | Suitable Materials | Advantages | Challenges |

|---|---|---|---|---|

| Surface Driven | Surface contact roll | Paper, film, foil, fabric | Dense, uniform rolls | Risk of core deformation |

| Center Driven | Torque at core | Films, wires, fibers | Precise tension control | Complexity as diameter increases |

| Spindle Driven | Direct spindle drive | Yarn, thread, bobbins | High accuracy, compact rolls | Limited to small-scale applications |

| Automatic | Fully automated | High-volume materials | High efficiency, minimal labor | Higher equipment cost |

| Manual | Operator-controlled | Small-batch jobs | Flexible, low cost | Low productivity, inconsistent rolls |

The integration of Take up winder systems into modern manufacturing delivers significant operational and economic benefits.

| Industry | Winding Target | Critical Requirements | Key Challenges |

|---|---|---|---|

| Textile | Yarn, filament | Uniform tension, neat rolls | Fragility of fine fibers |

| Wire & Cable | Conductors, optical fiber | Layered stability, high load capacity | Heavy reel handling |

| Plastics & Films | Sheets, packaging film | Smoothness, wrinkle-free rolls | Heat and stretch sensitivity |

| Paper & Printing | Paper, foil | Large master roll stability | Maintaining flatness, avoiding curl |

| Medical & Nonwovens | Nonwoven fabrics | Contamination-free, delicate handling | Easy tearing of lightweight fabrics |

When investing in a Take up winder, manufacturers must evaluate multiple factors:

The next generation of Take up winder systems is being shaped by digital transformation and sustainability imperatives.

The Take up winder may appear to be a modest piece of machinery, but in reality, it is the indispensable guardian of production continuity. Its role spans from the textile sector to cable production, from plastics to paper, from nonwovens to composites. Without it, modern manufacturing would face higher waste, greater inefficiency, and compromised product quality.

As industries pursue automation, digitization, and sustainability, the Take up winder is evolving into an intelligent, interconnected system. Equipped with sensors, data analytics, and automated handling, it ensures precision, reduces human intervention, and secures safer working conditions.

Far more than a mechanical accessory, the Take up winder embodies the principles of modern manufacturing: efficiency, consistency, safety, and continuous improvement. Its future will be defined by smarter controls, greener energy use, and tighter integration into digital production ecosystems—ensuring that it remains a cornerstone of industrial progress for decades to come.