Imagine an ordinary used PET plastic bottle. Its journey towards a new life begins when it arrives at a recycling facility and is shredded into small, flat pieces known as PET flakes. At this stage, however, these flakes are contaminated and, most critically, wet.

This moisture is the arch-nemesis of high-quality recycled plastic. If not removed, it causes severe problems in the final product, including imperfections, reduced strength, and poor viscosity during the melting process. So, how do we transform these damp, discarded fragments into a pristine, reliable raw material ready for manufacturing?

The answer lies in a crucial, often overlooked step that ensures these flakes are perfectly dried: the PET flakes dryer. This machine acts as the essential bridge, turning washed fragments into a valuable new material, making it the unsung hero of efficient rPET production.

To truly appreciate the role of the PET flakes dryer, one must view it not in isolation, but as the critical final stage in a meticulously coordinated pre-treatment line. Introducing moisture-laden, heavily soiled flakes directly into a dryer would be highly inefficient, consuming excessive energy while yielding subpar results. The dryer's performance is profoundly dependent on the effectiveness of the steps that come before it.

This preparatory phase is collectively known as the PET flakes washing line. Here, the flakes undergo a rigorous multi-stage cleansing process. This typically begins with a pre-wash to remove coarse contaminants, followed by a hot alkali wash that dissolves labels, adhesives, and other stubborn residues. Subsequent friction washers scrub the flakes against each other, physically dislodging any remaining impurities. The ultimate goal of this entire line is to produce flakes that are not only chemically clean but also have had the majority of their surface water removed. This is where a dedicated mechanical process comes into play.

After washing, the flakes are saturated with water. Sending them in this state to the thermal PET flakes dryer would force the dryer to expend immense energy simply on evaporating this free water, which is thermally inefficient. Therefore, a mechanical PET flakes dewatering step is indispensable. Equipment like dewatering centrifuges or screw presses spin the flakes at high speeds, using centrifugal force to forcibly eject the bulk of the surface moisture. This process is remarkably energy-efficient compared to thermal drying, as it utilizes mechanical action rather than heat.

The stark contrast in energy consumption between mechanical dewatering and thermal drying highlights why this sequence is so crucial. The table below provides a simplified comparison of the key operational parameters and objectives of these two interconnected stages:

| Parameter | Mechanical Dewatering (Pre-Drying Step) | Thermal Drying (Final Drying Step) |

|---|---|---|

| Primary Function | To remove free and surface moisture mechanically. | To remove residual bound and internal moisture thermally. |

| Energy Principle | Mechanical Kinetic Energy (Centrifugal Force). | Thermal Energy (Heated Air). |

| Energy Efficiency | Very High (Uses minimal electrical energy for a high water removal yield). | Lower (Thermal evaporation is inherently energy-intensive). |

| Moisture Reduction | Typically reduces moisture content from >50% down to 5-15%. | Further reduces moisture content from 5-15% down to <1% (or as required). |

| Key Outcome | Prepares the flakes for efficient thermal drying, significantly reducing the thermal load. | Achieves the final, precise moisture specification for high-quality rPET production. |

In conclusion, the PET flakes drying process is a tale of two halves. The initial, heavy lifting of water removal is done efficiently by mechanical dewatering. The PET flakes dryer then takes over to perform the precision finishing, eliminating the last traces of moisture to ensure the flakes meet the stringent quality standards required for the final product. Understanding this synergy is fundamental to optimizing the entire PET recycling equipment line for both maximum efficiency and superior output quality.

Having passed through the crucial pre-treatment stages of washing and dewatering, the PET flakes are now clean and have significantly reduced surface moisture. They are now ready for the final, precision-driven stage of their transformation. The PET flakes dryer operates on the fundamental principle of convective heat transfer, but its engineering is finely tuned to the specific requirements of PET material to ensure optimal results without thermal degradation.

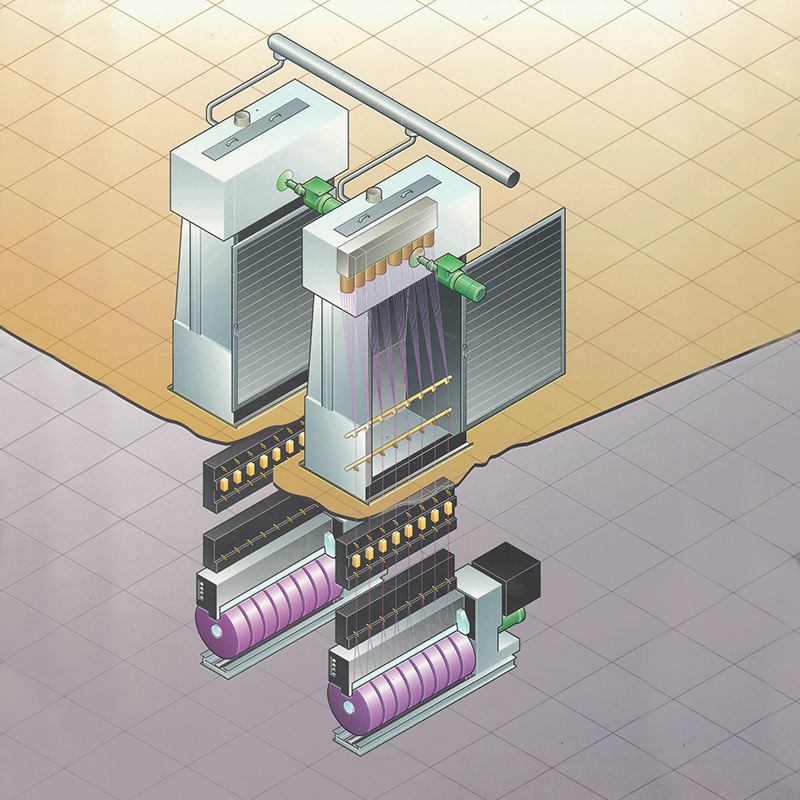

The process typically begins as the mechanically dewatered flakes, with a moisture content of approximately 5-15%, are fed into the dryer. The most common design for this application is a closed-loop convection dryer, often structured as a rotating drum or a vertical silo with an internal conveying system. Within this chamber, a stream of hot, dry air is circulated. This air acts as the heat transfer medium and moisture carrier. As the flakes are gently agitated and moved through the dryer, they are continuously exposed to this hot air. The heat energy from the air penetrates the flakes, causing the residual bound and internal moisture to evaporate. The now humidified air is then extracted from the chamber, passed through a condenser to remove the moisture, reheated to the precise temperature, and recirculated back into the system, making the process highly energy-efficient.

The efficacy and quality of the entire PET flakes drying process hinge on the precise control of three key parameters: temperature, airflow, and residence time. These variables are interdependent and must be carefully balanced to achieve the target moisture content of less than 1% while preserving the intrinsic viscosity (IV) of the PET, which is critical for the quality of the final rPET product.

The following table contrasts the operational conditions and outcomes between a properly optimized drying process and one that is poorly controlled, highlighting the critical role of precise engineering:

| Parameter | Optimized Drying Process | Poorly Controlled Drying Process |

|---|---|---|

| Drying Temperature | Precisely controlled, typically within a medium-temperature range (e.g., 160°C - 180°C). Sufficient to evaporate moisture efficiently without damaging the polymer. | Either too low (inefficient, leaving moisture) or too high (exceeding ~180°C), approaching the PET's glass transition temperature and causing degradation. |

| Airflow & Residence Time | Balanced to ensure a residence time of 20-40 minutes. Adequate, gentle agitation ensures uniform exposure to hot air and prevents clumping. | Insufficient time leads to "wet spots" and high residual moisture. Excessive time reduces throughput and may cause unnecessary heat history. |

| Air Dew Point (in Closed-Loop Systems) | Maintained at a very low dew point (e.g., -10°C to -20°C), indicating extremely dry air with a high moisture-carrying capacity. | A high air dew point means the air is saturated quickly, drastically reducing drying efficiency and extending the process time. |

| Final Moisture Content | Consistently achieves < 1%, and often as low as 0.5%, meeting the strictest specifications for high-end rPET production. | Inconsistent and often too high (> 1%), leading to quality issues in the final product. |

| Impact on PET Material | Preserves the Intrinsic Viscosity (IV) of the polymer. The flakes remain crystalline and free-flowing, ready for extrusion. | Causes IV drop (molecular breakdown) and potential yellowing due to overheating. Over-drying can make flakes sticky, causing clumping. |

| Energy Efficiency | High, as the closed-loop system with air recirculation and heat recovery minimizes thermal energy loss. | Low, due to inefficient heat use, potential heat loss, and longer cycle times required to achieve a passable result. |

In summary, the PET flakes dryer is far more than a simple heating chamber. It is a precision instrument where a delicate balance of thermodynamics and material science is managed. Its core function within the broader rPET drying mission is to apply just the right amount of heat for just the right amount of time, transforming the prepared flakes into a perfectly dry, high-quality raw material. This meticulous control is what enables the PET recycling equipment line to consistently output a product that can truly compete with virgin materials.

While we have examined the PET flakes dryer in the context of the immediate production line, its true significance is fully realized when we zoom out to view its function within the entire PET recycling ecosystem. This ecosystem spans from collection and sorting to the final creation of new products, and the dryer serves as a critical quality and economic gateway. Its performance directly influences not just the output of a single machine, but the viability and sustainability of the entire circular economy model for PET.

At the heart of this ecosystem is the comprehensive suite of PET recycling equipment. The dryer is not a standalone unit but an integrated component whose efficiency is leveraged by the upstream processes and whose output enables the downstream ones. For instance, the consistent quality of flakes from a sophisticated washing line allows the dryer to operate at peak thermal efficiency. Conversely, a reliably dry output ensures that the subsequent extrusion and pelletizing stages can run smoothly, without steam-induced voids (known as "splay") or a drop in the intrinsic viscosity of the melt. Therefore, the dryer acts as the linchpin that stabilizes the entire production chain.

Furthermore, the quality of the rPET drying process is a primary determinant of the value of the end material. The market for recycled PET is stratified; high-quality rPET that can be used in food-grade applications or high-performance textiles commands a premium price. This quality is defined by strict parameters, chief among them being ultra-low moisture content and high intrinsic viscosity. A superior PET flakes dryer is the key equipment that ensures these parameters are met consistently. It is the machine that transforms a washed, dewatered flake—which is still a semi-processed intermediate—into a certified, high-value raw material. In this sense, the dryer is not merely a processor; it is a value-amplifier.

The following table contrasts the broader implications of integrating a high-performance dryer versus relying on an inadequate system, illustrating its cascading impact on the recycling ecosystem:

| Aspect | Ecosystem with a High-Performance Dryer | Ecosystem with an Inadequate Dryer |

|---|---|---|

| Economic Viability | Enables production of premium, food-grade rPET, opening access to lucrative markets and ensuring a higher, more stable selling price. | Limits output to lower-grade rPET suitable for non-critical applications (e.g., fiberfill), which is subject to greater market price volatility and lower margins. |

| Throughput & Efficiency | Maintains a consistent and rapid cycle time, allowing the entire PET recycling equipment line to operate at its designed capacity without bottlenecks. | Creates a bottleneck. Downstream extrusion must slow down, or the line must stop frequently to address clumping or inconsistent moisture, reducing overall plant throughput. |

| Material Circularity | Produces rPET of such high quality that it can facilitate closed-loop recycling (bottle-to-bottle), truly advancing the circular economy. | Often results in downcycling (e.g., bottle-to-fiber), which is a linear path that eventually leads to the material being discarded. |

| Operational Stability | Provides a stable, predictable, and automatable process. Consistent flake quality minimizes disruptions in extrusion and pelletizing, reducing operational costs. | Leads to frequent operational issues: clogged hoppers, steam explosions during extrusion, and variations in pellet quality, increasing downtime and maintenance. |

| Environmental Footprint | Maximizes the energy investment of the entire washing and collection process by ensuring a high yield of usable material. Closed-loop systems minimize specific energy consumption per kg of output. | Wastes the embedded energy and resources of the upstream processes by producing a significant portion of off-spec material, undermining the environmental goals of recycling. |

| Brand & Off-taker Confidence | Builds trust with brand owners committed to using recycled content by guaranteeing a reliable supply of high-specification, clean rPET. | Creates supply chain uncertainty, as the inconsistent quality of the rPET flakes or pellets makes it a risky material for high-end product manufacturing. |

In conclusion, the PET flakes dryer transcends its functional role as a moisture-removal unit. It is a strategic asset within the PET recycling ecosystem. Its performance is a key determinant of the economic profitability, operational efficiency, and environmental integrity of the entire recycling endeavor. By ensuring the final and most critical quality transition, the dryer secures the value created at every previous stage, ultimately safeguarding the promise of a circular economy for plastics.

Our journey, tracing the path of a single plastic bottle fragment through the intricate stages of recycling, culminates here with a profound realization: the PET flakes dryer, while perhaps a single component in a vast mechanical lineup, exerts an influence that is disproportionately vast. It is the definitive gatekeeper between the past and the future of the material, the critical juncture where potential is either fully realized or irrevocably diminished. This unassuming piece of PET recycling equipment is, in essence, the guarantor of quality and the enforcer of the circular economy's promise.

Reflecting on the complete PET flakes drying process, we see a narrative of transformation. The journey begins with damp, contaminated fragments of uncertain value. It progresses through the essential preparatory stages of the PET flakes washing line and the mechanical efficiency of PET flakes dewatering. However, it is only upon entering the controlled environment of the dryer that the final metamorphosis occurs. Here, the application of precisely calibrated heat and airflow does not merely remove water; it eliminates uncertainty. It converts a vulnerable, intermediate product into a stable, high-value commodity ready to re-enter the manufacturing world as pristine rPET drying output. The dryer, therefore, is not just a processor of material but a transformer of value.

The ultimate success of the entire PET recycling mission hinges on this final step. One can operate the most advanced sorting, washing, and dewatering systems, but if the drying stage fails, the collective effort is compromised. The dryer protects the massive investment—in energy, machinery, and human labor—that has been made up to that point. It is the final and most critical quality control checkpoint, ensuring that every other component in the ecosystem of PET recycling equipment can function as intended and deliver on the overarching goal of true material circularity.

The following table synthesizes the transformative impact of the drying stage, contrasting the state of the material and the broader implications at the beginning versus the end of this crucial process:

| Aspect | The "Before" State: Post-Dewatering Flakes | The "After" State: Post-Drying rPET Flakes |

|---|---|---|

| Material Identity | A semi-processed intermediate; a commodity in flux. | A finished, high-value raw material; a certified-grade rPET. |

| Economic Value | Possesses potential value, but this is unstable and highly dependent on the next processing step. | Holds realized, maximum value, capable of commanding premium prices in markets for food-grade or high-performance materials. |

| Moisture Content & Stability | Hygroscopic and unstable (5-15% moisture). Prone to regrowth of microbes and chemical degradation if stored. | Stable and inert (<1% moisture). Suitable for long-term storage and global shipping without risk of degradation. |

| Downstream Process Impact | High risk for downstream processes. Causes steam explosions ("splay"), IV drop, and equipment strain during extrusion. | Enables optimal downstream processing. Ensures smooth extrusion, stable melt viscosity, and high-quality pelletizing. |

| Role in the Circular Economy | Represents a link in the chain; the circular loop is not yet closed and remains vulnerable to breakage. | Represents a closed loop; the material is now fully prepared to displace virgin PET in new manufacturing, completing the circle. |

| Environmental ROI | Embodies a partial Return on Investment; much of the embedded energy and resources from collection and washing remain at risk. | Secures the full Environmental ROI; the energy and resources invested in its recovery are fully capitalized upon by creating a viable virgin material substitute. |

In summary, the journey from a used plastic bottle to a new product is a story of incremental refinement and value restoration. The PET flakes dryer is the author of the final, decisive chapter in that story. It is a powerful demonstration that in modern industrial recycling, monumental impacts on our economy and our environment can hinge on the precise and reliable operation of what might be considered a "small" piece of equipment. Its role is a testament to the fact that in the pursuit of sustainability, there are no insignificant steps—only critical links in a chain, each one essential for holding the entire system together.

Achieving a moisture content of less than 1% is not arbitrary; it is a fundamental requirement for high-quality extrusion and the final product's performance. Residual moisture turns to steam during the high-temperature melting process in the extruder, causing two major issues: First, it leads to hydrolysis, which breaks down the polymer chains, reducing the material's intrinsic viscosity (IV) and mechanical strength. Second, the trapped steam creates bubbles and voids (known as "splay") in the final rPET pellet or molded product, leading to visual defects and structural weaknesses. Therefore, the primary function of the PET flakes dryer is to ensure this critical moisture specification is met consistently to produce a robust, reliable material.

A superior drying system does more than just remove water; it safeguards the polymer's integrity through precise control. Key features include:

Leveraging our extensive experience in precision machinery for the textile and chemical fiber industries, Jiaxing Shengbang Mechanical Equipment Co., Ltd. integrates these principles into our approach. Our background in developing advanced spinning machinery and operating plasma-coating equipment gives us a foundational understanding of precise thermal management and material handling, which are directly applicable to optimizing drying technology for plastic recycling.

The drying stage is a significant determinant of a plant's operational profitability. An inefficient dryer acts as a bottleneck, limiting the throughput of the entire PET recycling equipment line. More importantly, it is one of the largest consumers of thermal energy in the process. An optimized dryer, characterized by features like closed-loop air recirculation and heat recovery, dramatically reduces energy consumption per kilogram of output. Furthermore, by consistently producing high-specification, dry rPET flakes, the plant can access premium markets (like food-grade rPET), thereby maximizing revenue from its output. In essence, investing in an efficient dryer minimizes the two biggest cost factors—energy and downtime—while maximizing the value of the final product.