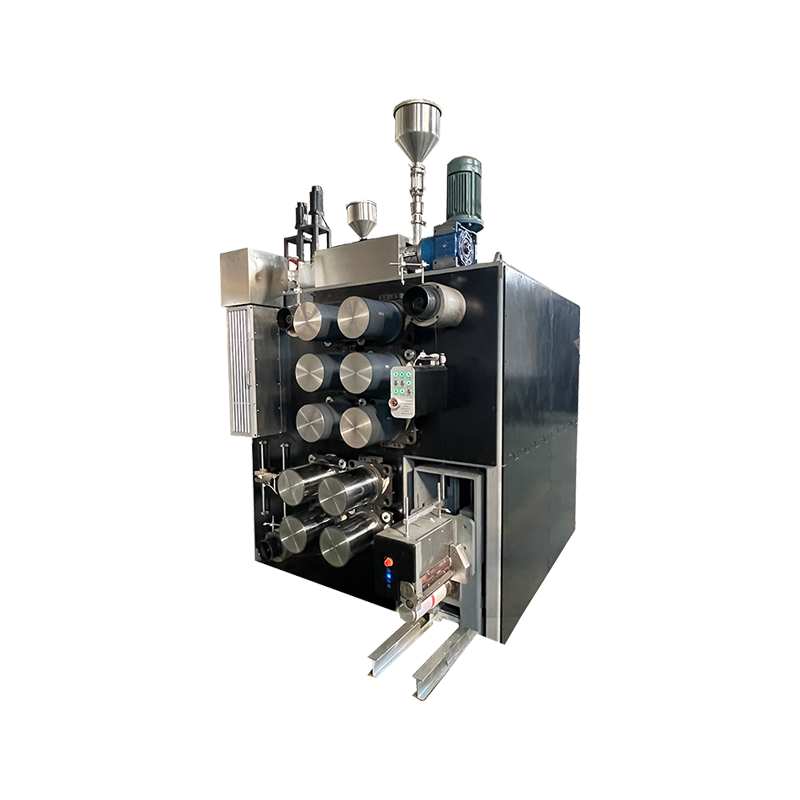

Our pilot spinning machine has been designed for the greatest level of flexibility. It is a stand-alone system for which all auxiliary units required for operation are integrated within the system. Hence, this pilot spinning machine is the ideal production tool for those yarn manufacturers who in addition to large orders, have to cope with a broad range of products in small lots and be able to react quickly to a dynamic market.

With our machine, market changes do not automatically equate to investing in a new machine, but simply purchasing a customized retooling package. For this reason, you will always be able to utilize an optimal concept for the latest products, and all at minimal cost. The entire facility and its key components meet the e-save standard: With an energy consumption at least 20% lower than that of common commercial equipment, it proves a sound investment in the future.

By now, our pilot spinning machine, with its flexible process including UDY, POY, FDY, HOY, and ITY, has successfully spun PET, PA, PP, PGA, PLA, PPS, PBS, POM, PAR and PEEK.