In the intricate and highly competitive world of synthetic fiber manufacturing, efficiency, consistency, and scalability are not just advantages—they are necessities for survival and growth. At the heart of this modern manufacturing landscape lies the POY spinning production line, a sophisticated and integrated system engineered to transform raw polymer chips into a vital intermediate textile product with unparalleled speed and precision. This process has fundamentally revolutionized the industry by enabling the high-volume, continuous production of a yarn form that serves as the essential precursor to a vast array of final textiles, from everyday apparel to high-performance technical fabrics.

Understanding what POY (Partially Oriented Yarn) represents is crucial to appreciating the value of the production line that creates it. POY is a specific type of filament yarn produced at extremely high speeds and, as its name clearly indicates, is only partially drawn during its initial formation. It is intentionally designed as an intermediate product, meaning it is not directly ready for end-use applications like knitting or weaving. Instead, POY is strategically manufactured to be further processed into other yarn types, most notably DTY (Drawn Textured Yarn), through subsequent processes of drawing and texturing. This partial orientation imbues the yarn with a critical balance of molecular stability and latent potential, retaining the essential ability to be stretched, crimped, and set in a later stage. This unique characteristic is the fundamental key to creating the bulk, stretch, and hand feel that define textured fabrics.

An overview of the POY spinning process reveals a marvel of continuous, high-speed industrial operation. The journey begins with the precise melting of polymer chips, typically polyethylene terephthalate (PET) or polyamide, in a specialized extruder. The resulting molten polymer is then meticulously conditioned, passing through a filtration system and a metering pump before being forced through the microscopic holes of a spinneret to form multiple continuous filaments. These nascent filaments are immediately cooled and solidified by a controlled quenching system and are then wound onto bobbins at velocities that can exceed six thousand meters per minute. It is this incredible speed of the winding, or take-up speed, that imparts the yarn’s defining partial orientation, aligning the polymer molecules just enough to provide stability for handling while leaving room for further drawing.

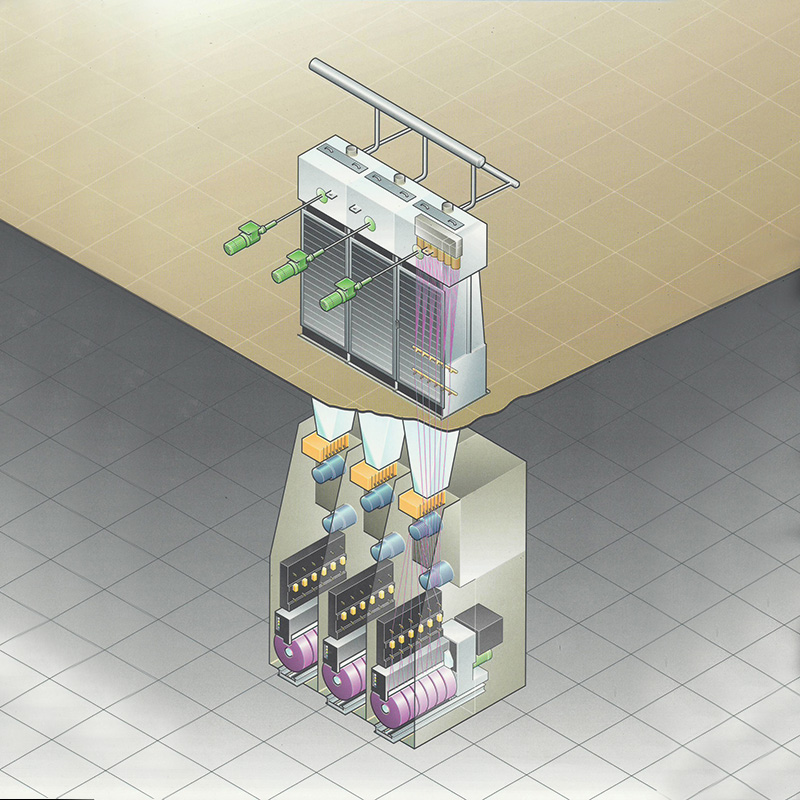

The key components of a POY spinning production line work in a seamless, synchronized symphony. Each section, from the raw material handling and extrusion system to the precision winding units, has a specific and critical function. The harmonious operation of these components—the extruder, spin packs, quenching chamber, godet rolls, and high-speed winders—is what allows for the relentless, high-volume production of consistent, high-quality partially oriented yarn. This integrated system represents a significant capital investment but one that pays continuous dividends in output and efficiency for modern textile manufacturers.

A POY spinning production line is not a single machine but a complex amalgamation of several high-tech components that function in a perfectly sequenced and integrated manner to produce yarn. Each component plays a specific and non-negotiable role in the process, and the failure or suboptimal performance of any single unit can compromise the entire line’s output and quality.

The entire process is initiated within the extruder and melt preparation system, where solid, often crystalline, polymer chips are transformed into a uniform, viscous liquid. The extruder itself is the workhorse of this stage, utilizing a rotating, heated screw to progressively melt the polymer chips as they are conveyed forward. The melt preparation system that follows is equally critical; it ensures the molten polymer is free of impurities through sophisticated filtration, and it maintains the polymer at a perfectly uniform temperature and pressure. Consistency at this stage is paramount, as any fluctuations in viscosity, temperature, or the presence of gel particles or contaminants will inevitably lead to yarn defects such as denier variation, broken filaments, or poor dyeability later on.

Following its preparation, the molten polymer is distributed under high pressure to the spinning beam. This is a complex, thermally controlled manifold designed to evenly distribute the polymer melt to a battery of spinnerets. A spinneret is a critical precision component, typically a disc made of specialized alloys, containing anywhere from dozens to hundreds of meticulously engineered micro-holes. The molten polymer is forced through these tiny capillaries, emerging as a corresponding number of continuous, liquid filaments. The geometry, finish, and consistency of these holes are vital, as they directly determine the cross-sectional shape and ultimate uniformity of each individual filament within the yarn bundle.

Upon exiting the spinneret, the hot, liquid filaments are immediately and rapidly cooled in the quenching system. This stage is where solidification occurs, locking in the initial molecular structure. A controlled, laminar flow of cool air is blown across the filament bundle in a specific cross-flow or radial pattern. The precision of this quenching process is a critical determinant of the yarn’s ultimate properties. The speed, temperature, humidity, and uniformity of the airflow must be meticulously controlled to ensure all filaments cool at the same rate. An uneven quench will result in variations in crystallinity and orientation across the yarn, leading to poor mechanical properties and potential issues in downstream processing.

After solidification, the filaments are gathered into a cohesive yarn and pass through the draw-off system, typically consisting of one or more sets of godet rolls. These are heated or unheated rollers that control the tension and speed of the yarn as it travels toward the winder. The differential speed between these godet sets and the final winder provides the minimal draw ratio that characterizes POY. This controlled stretching is what orients the polymer molecules along the filament axis, providing the yarn with its partial orientation, which translates to adequate strength for winding and handling while retaining a high degree of drawability in the texturing process.

The final stage in the line is the high-speed winding system, a technological marvel in its own right. This is where the finished POY is collected onto large bobbins or packages. Modern POY spinning production lines employ winders capable of operating at surface speeds exceeding 6,000 meters per minute. These winders must exhibit exceptional precision in controlling traverse mechanisms and tension to ensure the yarn is wound into a stable, compact, and uniformly structured package. The package build quality is essential, as it must withstand the rigors of transportation and unwind perfectly during the high-speed draw-texturing process without causing tangles or breaks.

Table 1: Core Components of a POY Spinning Production Line and Their Functions

| Component | Primary Function | Key Impact on Yarn |

|---|---|---|

| Extruder & Melt System | Melts, filters, and homogenizes polymer | Determines polymer uniformity and purity |

| Spinneret | Forms molten polymer into continuous filaments | Defines filament count and cross-section |

| Quenching System | Cools and solidifies filaments | Sets initial molecular structure and orientation |

| Godet Rolls | Controls yarn tension and applies initial draw | Imparts the partial orientation |

| High-Speed Winder | Packages yarn onto bobbins at high speed | Determines package stability for downstream use |

The transformation of raw polymer into Partially Oriented Yarn is a continuous, tightly controlled, and highly automated process. Each step in the POY spinning production line is designed to build upon the previous one, ensuring a consistent and high-quality output that meets precise specifications.

The process initiates with the feeding of dried polymer chips—most commonly PET, but also polypropylene or nylon—into the hopper of the extruder. Inside the extruder barrel, the chips are heated through a series of precisely controlled zones via electric heaters and the mechanical shear of the rotating screw. This action gradually melts the chips into a homogeneous, viscous fluid. The molten polymer is then forced through a series of filtration layers, often consisting of metal sand and fine screens, to remove any solid impurities, catalyst residues, or gel particles that could cause spinneret clogging or yarn defects. A high-precision metering pump, typically a gear pump, then receives the filtered melt. This pump is the heart of the throughput control, delivering an exact and constant volume of polymer to the spinning block, ensuring every spinneret hole receives an identical flow, which is critical for denier uniformity.

The metered polymer melt is distributed through the spinning beam to the spinnerets. As it is extruded through the fine holes of the spinneret, it forms multiple thin streams of liquid polymer. These streams immediately enter the quenching chamber, where they are exposed to a conditioned cross-flow of air. The air flow, carefully controlled for temperature, humidity, and velocity, rapidly extracts heat from the filaments, causing them to solidify. The quenching conditions are among the most critical parameters in the entire process. The rate of cooling significantly influences the development of the amorphous and crystalline structure within the polymer. Too rapid a quench can lead to a highly amorphous and unstable structure, while too slow a quench can allow excessive crystallization, making the yarn brittle and difficult to draw later. The goal is a uniform and controlled solidification that creates a stable yet drawable filament.

Upon exiting the quench chamber, the now-solid filaments are converged into a single yarn strand, often treated with a spin finish application to provide lubrication, reduce static, and ensure cohesion. The yarn then passes over a set of godet rolls. The first set, running at a base speed, guides the yarn. The final godet set or the winder itself operates at a significantly higher speed. This speed differential, often expressed as a draw ratio between 1.1 and 1.8, gently stretches the yarn. This stretching action aligns the long-chain polymer molecules along the filament axis, a process known as orientation. This molecular alignment dramatically increases the tensile strength of the yarn while reducing its elongation at break, creating the defining properties of POY. The yarn, now partially oriented, is finally wound onto a bobbin by a high-speed automatic winder. The winder must maintain perfect tension control and traverse guidance to build a package that is stable, free of defects, and ideal for transportation and subsequent processing on draw-texturing machines.

The evolution of the POY spinning production line is a story of relentless innovation aimed at enhancing efficiency, improving quality, and reducing the environmental footprint. Modern lines are integrated with sophisticated technologies that make them smarter, faster, and more sustainable than ever before.

Contemporary POY spinning production lines are epitomized by their high degree of automation. The entire process, from polymer chip feeding to doffing of full bobbins, is managed by an integrated control system. Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) act as the central nervous system, continuously monitoring and adjusting thousands of parameters. Supervisory Control and Data Acquisition (SCADA) software provides operators with a comprehensive graphical interface, allowing for real-time visualization of the entire line’s performance, from extruder temperatures and pump speeds to winder tensions and production rates. This automation minimizes human error, ensures recipe consistency, and allows for rapid troubleshooting, significantly enhancing overall equipment effectiveness (OEE).

The pursuit of higher productivity has driven remarkable advancements in high-speed spinning technology. Modern winders are engineering marvels, capable of operating at take-up speeds exceeding 6,000 meters per minute. This is achieved through innovations such as lightweight composite materials for traverse mechanisms, advanced spindle drives, and sophisticated tension control systems that can make micro-adjustments in milliseconds. These high speeds are not just about output; they also influence yarn properties. Higher winding speeds can lead to higher orientation and better stability in the POY, allowing for more efficient downstream processing.

As energy costs rise and environmental regulations tighten, sustainability has become a core design principle. Modern POY spinning production lines incorporate numerous energy efficiency innovations. High-efficiency AC motors with variable frequency drives (VFDs) have replaced older fixed-speed motors, allowing power consumption to be precisely matched to the load. Heat recovery systems are now common, capturing waste heat from the extruder barrel and quenching air to preheat incoming air or for use elsewhere in the plant. Furthermore, optimized quenching system designs reduce the energy required for air conditioning, while advanced polymer drying technology minimizes energy use in preparing the raw material.

Quality control has shifted from offline laboratory testing to continuous online monitoring. Advanced sensors are integrated directly into the line to measure key yarn properties in real-time. Laser gauges continuously measure yarn denier, capacitance sensors detect oil application uniformity, and evenness testers can identify thick and thin places as the yarn is wound. This data is fed back to the control system, which can make automatic corrections to maintain quality within tight tolerances. Beyond immediate control, this vast dataset is stored for analysis, enabling predictive maintenance, process optimization, and traceability for every bobbin produced.

Table 2: Impact of Advanced Technologies on POY Line Performance

| Technology | Application in POY Line | Benefits |

|---|---|---|

| Automation & SCADA | Centralized control of all process parameters | Improves consistency, reduces operator error, enables rapid response |

| High-Speed Winding | Package formation at >6000 m/min | Dramatically increases production output and yarn orientation |

| Variable Frequency Drives (VFDs) | Controlling motor speeds for pumps, fans, winders | Reduces energy consumption by matching power to demand |

| Online Quality Sensors | Real-time measurement of denier, oil, evenness | Allows instant correction, ensures consistent quality, reduces waste |

As a semi-finished product, POY is the fundamental building block for a vast spectrum of final goods. Its inherent versatility allows it to be transformed into various yarns that serve diverse markets, from fashion to heavy industry.

The primary destination for POY is the textile apparel sector, where it is almost exclusively converted into Drawn Textured Yarn (DTY). The texturing process imparts bulk, stretch, and a soft hand to the yarn, making it ideal for a multitude of applications. In apparel, POY-based DTY is the backbone of stretch fabrics used in sportswear, activewear, leggings, and intimate apparel. Its durability and dyeability also make it suitable for everyday knitwear, t-shirts, dress materials, and linings. In home furnishings, the same textured yarns are used to create plush, comfortable, and durable fabrics for upholstery, curtains, drapes, bedding, and carpets. The aesthetic possibilities are nearly endless, influenced by the original POY’s denier, filament count, and cross-section.

Beyond clothing and home decor, the strength and consistency of POY and its fully drawn derivatives make them suitable for demanding technical applications. While POY itself is not used directly, it is the preferred precursor for producing high-tenacity (HT) yarns. These strong, dimensionally stable yarns are woven or knitted into geotextiles for soil stabilization, road construction, and erosion control. In the automotive industry, they are found in tire cord, seat belts, airbags, and interior trims. Other industrial applications include sewing threads, conveyor belts, ropes, cords, and even fabrics for protective clothing and specialized filtration systems. The reliability of the POY spinning production line in producing a uniform feedstock is critical for these high-performance applications.

The decision to invest in a POY spinning production line is significant and must be weighed against its considerable advantages and inherent challenges.

The dominance of POY technology is due to its compelling benefits. Firstly, it offers exceptionally high production rates, with single lines producing tons of yarn per day, enabling manufacturers to achieve economies of scale unmatched by other spinning technologies. This leads directly to superior cost-effectiveness, as the high output amortizes the capital investment over a large volume, and the high automation reduces labor costs per kilogram of yarn. Furthermore, the process offers tremendous versatility; by simply changing the spinneret, polymer, or process parameters, a single line can produce a wide range of yarn counts and cross-sections, allowing a manufacturer to quickly adapt to market trends. Finally, the controlled environment produces yarn of exceptional and consistent quality, with high uniformity in denier and strength, which reduces downstream processing problems and ensures a premium end-product.

However, these advantages come with substantial challenges. The most significant barrier is the high initial investment cost for the machinery, auxiliary equipment, and facility requirements. Secondly, operating these complex lines requires a high level of technical expertise; personnel must understand polymer science, mechanics, electronics, and process engineering to effectively run and maintain the line. This reliance on skilled labor can be a constraint. Finally, maintenance and downtime are critical considerations. The line is a continuous process, and any unplanned stoppage results in massive production losses. A rigorous and proactive preventive maintenance schedule is essential to maximize uptime and protect the substantial investment.

The future of the POY spinning production line is being shaped by the dual forces of digitalization and sustainability. The integration of Artificial Intelligence (AI) and Internet of Things (IoT) platforms will lead to “smart factories” where lines self-optimize, predict maintenance needs, and minimize quality deviations autonomously. Concurrently, the drive for sustainability will accelerate the adoption of technologies for processing recycled PET (rPET) and bio-based polymers directly on standard lines. Furthermore, the development of new polymer materials with enhanced properties will expand the applications of POY into new realms of technical textiles. These trends promise to make the POY spinning production line not just more efficient, but also more adaptable and responsible, securing its central role in the future of textile manufacturing.

The POY spinning production line is far more than just machinery; it is the foundational engine of the modern synthetic fiber industry. Its ability to efficiently produce a consistent, high-quality, and versatile intermediate product has made it an indispensable link in the global textile supply chain. While the challenges of capital cost and technical complexity are real, the advantages of unparalleled productivity, cost efficiency, and quality control make it a compelling investment for any serious player in the field. As the industry marches towards a future of greater digital integration and environmental stewardship, the POY spinning production line will continue to evolve, remaining the cornerstone upon which innovation in textile manufacturing is built.