In the textile industry production system, the stable and efficient operation of spinning equipment is the basis for improving production efficiency and ensuring product quality. The stability of TMT Parts (TMT components), which are composed of the core of spinning equipment, directly determines the overall performance of the equipment. With the intensification of competition in the textile industry and the growth of market demand for high-quality yarns, optimizing the stability of TMT Parts has become a key issue in the development of the industry. Through technological innovation, material upgrades and process improvements, many enterprises have made significant progress in improving the stability of TMT Parts, providing a solid guarantee for the efficient operation of spinning equipment.

During long-term continuous operation of traditional spinning equipment, failure problems caused by fluctuations in TMT Parts are common. For example, wear of transmission components, loose bearings and deformation of key structural parts will cause equipment operation accuracy to decrease, resulting in uneven yarn thickness and increased breaking rate, which seriously affects production efficiency and product quality. In addition, frequent equipment failures not only increase maintenance costs, but also cause delays in production plans due to downtime, causing direct economic losses to the company.

At the same time, the modern textile industry is developing towards intelligence and rapidity. New spinning equipment puts higher demands on the stability of TMT Parts. In high-speed operation, components need to withstand greater mechanical stress and dynamic load; in intelligent production mode, the equipment requires almost strict accuracy consistency and reliability of components. Therefore, optimizing the stability of TMT Parts has become an inevitable choice to meet the industry's upgrade needs and promote the high-quality development of the textile industry.

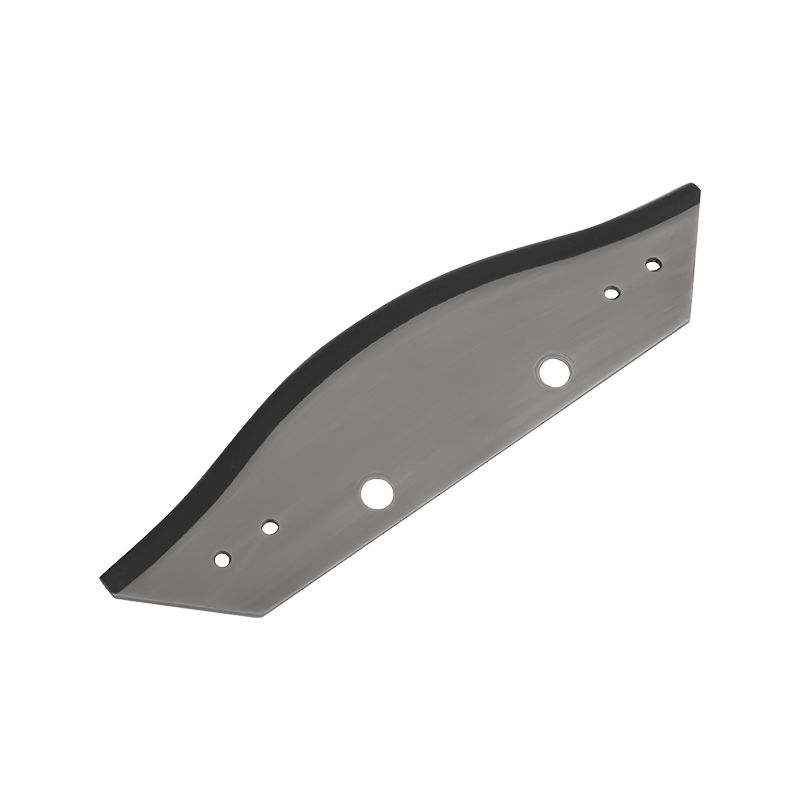

In terms of material selection, the industry has increased the research and development and application of high-performance materials. For key components that bear high loads in TMT Parts, such as drive shafts, gears, etc., high-strength alloy steel or special alloy materials are used to improve the strength, toughness and wear resistance of the material by adding rare metal elements and optimizing heat treatment processes. These materials can not only effectively reduce the wear rate of components during long-term use, but also reduce the risk of fracture caused by fatigue, ensuring the stability of TMT Parts at the root.

Innovation in manufacturing processes is the core link in stability optimization. The wide application of precision machining technology has significantly improved the manufacturing accuracy of TMT Parts. The CNC machining center ensures that the fitting accuracy of parts reaches the optimal state through micron-level dimensional control and surface finish processing, and reduces operating instability factors caused by assembly errors. In addition, advanced surface treatment processes, such as nanocoating, laser quenching, etc., form a dense protective layer on the surface of parts, enhancing its corrosion and wear resistance and further extending its service life.

At the design level, enterprises have introduced computer-aided design (CAD) and finite element analysis (FEA) technologies to optimize the structure of TMT Parts. By simulating the stress conditions of components under different working conditions, adjusting structural parameters, eliminating stress concentration points, and enhancing the stability of the overall structure. At the same time, the application of modular design concept makes the installation, disassembly and maintenance of TMT Parts more convenient, reducing the impact of improper maintenance operations on stability.

The improvement of TMT Parts' stability has brought multiple positive impacts on the operation of spinning equipment. First, the equipment failure rate has been greatly reduced. With its higher wear resistance and reliability, the optimized TMT Parts effectively reduces the number of downtime caused by component damage, significantly extends the continuous operation time of the equipment, and improves production efficiency by more than 20%. Secondly, product quality is effectively guaranteed. Stable-operated spinning equipment can ensure that the uniformity, strength and other indicators of the yarn meet high standards, reduce the defective rate, and enhance the market competitiveness of the enterprise.

From the perspective of cost control, TMT Parts stability optimization brings significant economic benefits. The reduced frequency of equipment maintenance and component replacement frequency directly reduces the maintenance costs of the enterprise; the improvement in production efficiency brought about by efficient and stable operation of the equipment indirectly dilutes the production cost of the unit product. In addition, a stable production condition helps enterprises better formulate production plans, reduce the risk of order delays caused by equipment failures, and maintain the company's reputation and customer relationships.

Despite the many achievements in TMT Parts stability optimization, the industry still faces challenges and opportunities. As textile equipment develops towards higher speeds and more intelligent directions, the stability requirements for TMT Parts will continue to increase. In the future, the research and development of new materials will become a key breakthrough point, such as smart materials with self-healing functions, ultra-light and high-strength composite materials, which are expected to further improve the performance of parts.

At the same time, the in-depth application of digital technology will provide a new path for stability optimization. Through IoT technology, the operating status of TMT Parts is monitored in real time, and big data analysis is used to predict potential failures to achieve preventive maintenance; combined with artificial intelligence algorithms, the operating parameters of the equipment are dynamically adjusted to ensure that TMT Parts are always in the best working state. In addition, the concept of green manufacturing will also promote stability optimization toward a more environmentally friendly and sustainable direction, and the development of low-energy and long-life TMT Parts will become a new trend in the industry.