Against the backdrop of the development of the automobile industry towards high reliability and long life, Spray Coating (spray coating process) is a key technology to improve the surface performance of parts, and its wear resistance characteristics are increasingly widely used in the field of automotive accessories. The wear-resistant spraying process significantly improves the wear, corrosion and impact resistance of accessories by forming high-performance coatings on the surface of metal or non-metal substrates, and has become an important means for automobile manufacturers to optimize product quality and reduce maintenance costs. This article will deeply analyze the practical value of wear-resistant Spray Coating in the field of automotive accessories from technical principles, application scenarios, performance advantages and industry trends.

The core of the wear-resistant spraying process lies in uniformly adhering wear-resistant materials (such as metal alloys, ceramic particles, polymer composite materials, etc.) to the surface of the accessories through high-speed spraying or high-temperature melting to form a coating with special physical and chemical properties. According to the process type, it can be divided into thermal spraying (such as plasma spraying, supersonic flame spraying), electrostatic spraying, powder spraying, etc. Different processes are suitable for accessories with different materials and performance requirements.

Compared with traditional surface treatment technologies (such as electroplating, heat treatment), wear-resistant Spray Coating has significant advantages:

Wide material adaptability: coatings can be formed on the surfaces of various substrates such as steel, aluminum, plastic, etc., and the coating materials can be flexibly selected according to wear resistance requirements. For example, the hardness of tungsten carbide ceramic coating can reach HRC above 60, far exceeding ordinary metal substrates;

Significant performance improvement: the coating thickness can be precisely controlled (from tens of microns to several millimeters), effectively fills the surface defects of the substrate, improves surface hardness, wear resistance and corrosion resistance. According to the inspection data, the wear life of accessories treated with wear-resistant spraying can be extended by 3-5 times;

Highly environmentally friendly: Some new processes (such as solvent-free powder spraying) can reduce VOC emissions, comply with global environmental protection regulations, and are more sustainable than electroplating processes.

(I) Engine system accessories

The piston ring, valve conduit, crankshaft and other accessories inside the engine are subject to severe wear under high temperature, high pressure and high speed motion environments. The supersonic flame spraying process coats the surface of the piston ring with chromium carbide alloy coating, which can form a protective layer with high hardness and high temperature resistance, reducing friction coefficient while reducing fuel leakage and improving engine efficiency. After the valve conduit is coated with plasma spray ceramic coating, the wear resistance is significantly improved, which can effectively reduce the wear between the valve and the conduit and extend the overall engine life.

(II) Chassis and transmission system accessories

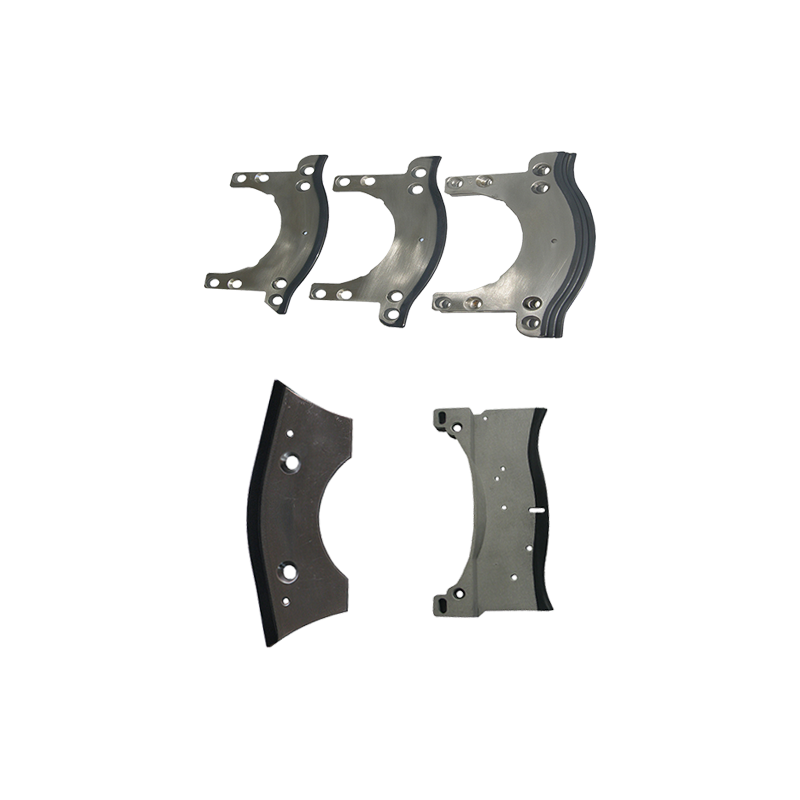

The suspension arms, steering joints, half shafts and other accessories in the chassis are exposed to complex road conditions and corrosive environments for a long time, and are prone to increased gaps and reduced handling accuracy due to wear. The electrostatic spraying process is used to coat the polymer wear-resistant coating on the surface of the suspension arm, which can achieve corrosion and friction reduction effects at the same time; the gear shaft of the transmission system can withstand higher torque loads by thermally spraying the metal cermet composite coating, reducing gear meshing wear and reducing transmission noise.

(III) Body and exterior accessories

The sill beams, wheel arches, chassis armor and other parts are susceptible to sand and gravel impact and rain and snow corrosion. They are wear-resistant Spray Coating sprays polyurea elastomer or rubber-based coating to form a flexible wear-resistant layer, effectively resisting gravel impact and preventing rust. Exterior trim such as bumper brackets, luggage racks, etc., are coated with wear-resistant polyester coating using powder spraying, which can improve surface hardness and scratch resistance, while achieving rich color effects.

The performance of Spray Coating depends on the core indicators such as coating adhesion, hardness, thickness uniformity and environmental aging resistance:

Adhesion: The bond strength of the coating and substrate is detected by the lattice method (ISO 2409) or the pull-off method (ASTM D4541). The qualified standards usually require adhesion ≥5MPa;

Hardness: Use a microhardness meter (such as Vickers hardness HV) to measure the coating hardness. The hardness of ceramic coatings must reach HV above 1000, and the hardness of metal alloy coatings must be ≥ HV 500;

Wear resistance: The wear life of the coating is evaluated through abrasive wear test (such as ASTM G65). The test conditions include abrasive type, load, sliding distance, etc. The wear weight of the high-quality coating should be ≤0.1g/1000 cycles;

Corrosion resistance: Salt spray test (ISO 9227) is a common method to detect the corrosion resistance of the coating. Automobile accessories coatings usually need to pass 1000 hours of salt spray test and there is no obvious rust on the surface.

The International Organization for Standardization (ISO) and the Automobile Industry Association (such as SAE and IATF) have clear specifications for the process parameters, coating performance and detection methods of wear-resistant Spray Coating. Automobile manufacturers must select corresponding standards based on the use environment of the accessories to ensure that the coating performance meets the design requirements.

(I) Intelligent process upgrade

With the popularization of Industry 4.0 technology, wear-resistant Spray Coating is gradually developing towards intelligence. For example, by installing a laser ranging sensor on the robot arm, dynamic adjustment of the spray trajectory and real-time monitoring of the coating thickness are achieved; big data analyzes the correlation model of process parameters and coating performance, and optimizes the spraying scheme to improve yield rate; introduces an AI visual inspection system to identify and sort the coating surface defects (such as bubbles and leaks) at high speed to reduce manual inspection costs.

(II) Green Materials and Process Innovation

The stricter environmental regulations promote the transformation of wear-resistant Spray Coating toward low pollution and low energy consumption. The application of green materials such as bio-based wear-resistant coatings (such as vegetable oil-based polyurethanes) and recyclable powder coatings is becoming increasingly widespread; new processes such as low-temperature plasma spraying and cold spraying are in line with the automotive industry's carbon neutrality goal by reducing energy consumption and reducing harmful gas emissions. In addition, the breakthrough in waste coating recycling and reuse technology has further improved the environmental friendliness of wear-resistant spraying processes.

(III) Breakthrough in composite coating technology

The performance bottleneck of single-material coatings is being broken through through composite coating technology. For example, the double-layer structure design of "metal transition layer + ceramic wear-resistant layer" can solve the problem of mismatch between the thermal expansion coefficient of the ceramic coating and the metal substrate and improve the coating binding force; the nanocomposite coating can significantly enhance the fatigue resistance and self-lubricating ability of the coating by introducing nano-scale fillers (such as graphene and carbon nanotubes), providing a better solution for automotive accessories under extreme operating conditions.

The wear-resistant Spray Coating process has become an indispensable key technology in the automotive industry with its significant advantages in improving the performance of automotive parts, extending service life and reducing maintenance costs. With the continuous innovation of intelligent, green and composite coating technologies, in the future, Spray Coating will show greater application potential in emerging fields such as new energy vehicles and autonomous driving, and promote the development of the automotive industry to a higher quality and more sustainable direction.