In the world of textile machinery, Barmag bearings play a crucial role in ensuring smooth and efficient operation. Among the various types of bearings, certain specialized bearings are designed to withstand the high speeds and mechanical stresses of modern textile equipment. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the performance and lifespan of these components.

This article aims to provide a comprehensive guide on these bearings, covering installation techniques, maintenance strategies, common troubleshooting methods, and performance optimization in challenging environments. By following these guidelines, operators and technicians can ensure the reliable operation of their equipment and prevent costly downtime.

Bearings are essential components in textile machinery, enabling smooth rotation and reducing friction between moving parts. Understanding their structure, function, and operational requirements is crucial for maintaining efficient production.

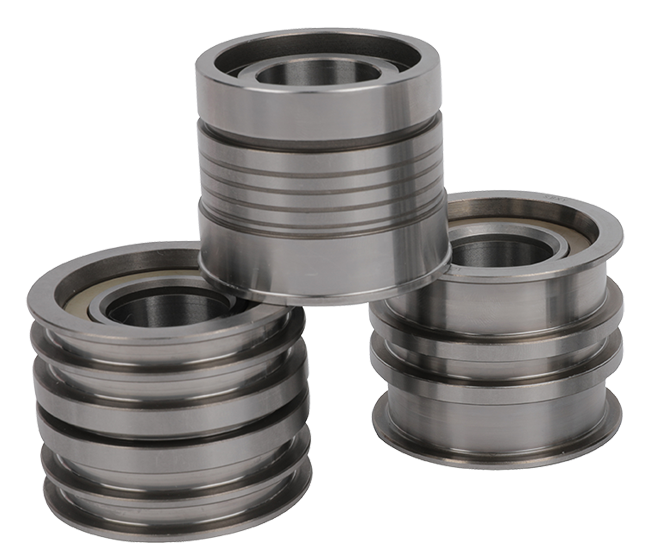

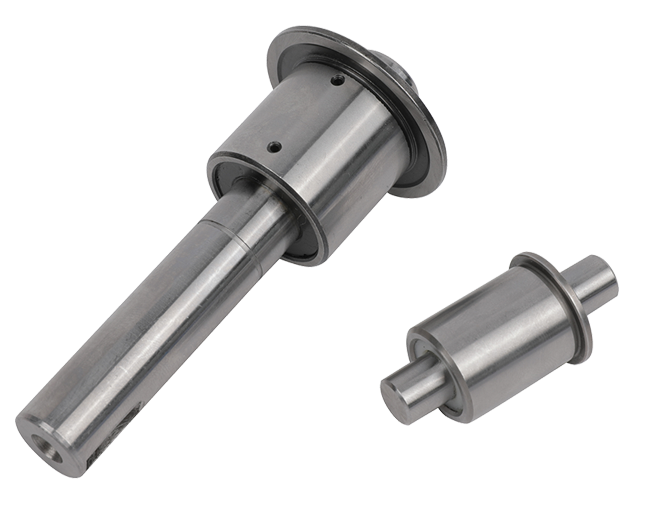

These bearings are typically designed to handle high speeds, heavy loads, and continuous operation. Key components include the inner and outer rings, rolling elements, and cages that ensure proper alignment and load distribution. Selecting the right type of bearing for a specific application depends on factors such as load capacity, rotational speed, and environmental conditions.

In addition, operating conditions like temperature, humidity, and contamination can significantly affect performance. High temperatures, for instance, can impact lubrication efficiency and accelerate wear, while exposure to dust or fibers can lead to premature failure. Proper monitoring and preventive measures are therefore vital to maintain optimal bearing performance.

By understanding the basics of these bearings, operators and maintenance personnel can better plan installation, maintenance, and troubleshooting procedures, ensuring reliability and longevity in textile operations.

| Parameter | Recommended Range / Value | Notes / Considerations |

| Shaft Diameter Tolerance | ±0.01 mm | Ensures proper press or thermal fit |

| Housing Bore Tolerance | ±0.02 mm | Prevents misalignment and uneven load |

| Axial Clearance (C0) | 0.02 – 0.05 mm | Adjust based on operating temperature and load |

| Lubricant Type | Grease or Oil | Choose based on speed, temperature, and environment |

| Installation Temperature Limit | ≤80°C (for thermal fit) | Avoids material distortion or premature wear |

| Operating Speed | Up to 3000 RPM | Ensure bearing type matches machine specifications |

| Maintenance Task | Frequency | Details / Notes |

| Visual Inspection | Weekly | Check for wear, dirt, and unusual vibration |

| Lubricant Replenishment | Monthly | Follow manufacturer or equipment guidelines |

| Cleaning | Monthly | Remove dust, fibers, and debris from housing |

| Temperature Check | Weekly | Ensure operating temperature is within limits |

| Alignment Check | Quarterly | Verify shaft and bearing alignment |

| Full Performance Audit | Annually | Inspect all bearings and replace if necessary |

| Step | Action Details | Tools / Notes |

| Inspection | Identify signs of wear or failure | Noise check, vibration analysis |

| Preparation | Shut down machine, clean work area | Safety gloves, clean cloth |

| Bearing Removal | Loosen bolts, use puller or hydraulic press | Avoid applying force to inner ring |

| Shaft/Housing Check | Inspect for wear, corrosion, or deformation | Measure tolerances |

| New Bearing Installation | Press-fit or thermal-fit, ensure proper alignment | Hydraulic press, heating/cooling as needed |

| Lubrication & Testing | Apply lubricant, rotate machine manually | Check smooth operation and load distribution |

| Problem | Possible Cause | Recommended Action |

| Excessive Noise | Poor lubrication, contamination | Clean bearing, apply correct lubricant, check alignment |

| Overheating | Excess load, friction, low lubrication | Reduce load, check lubricant, inspect bearing |

| Vibration | Misalignment, worn bearings, imbalance | Realign shaft, balance load, replace damaged bearing |

| Premature Wear | Contamination, poor installation, high temperature | Improve sealing, correct installation, monitor temperature |

| Lubricant Leakage | Seal failure or excess lubricant | Replace seals, use correct lubrication amount |

| Optimization Strategy | Recommended Approach | Benefits / Notes |

| Lubricant Selection | High-temp grease or oil | Reduces lubricant breakdown and wear |

| Temperature Monitoring | Weekly or real-time sensors | Detects overheating before damage occurs |

| Heat Dissipation | Cooling systems, airflow enhancement | Maintains stable operating temperatures |

| Bearing Material Selection | Heat-resistant steel or ceramic bearings | Maintains mechanical strength at high temps |

| Seal Improvement | High-temp seals | Prevents contamination and lubricant leakage |

In textile machinery, Barmag bearings play a critical role in ensuring smooth operation, reducing friction, and maintaining overall equipment reliability. Proper installation, regular maintenance, timely troubleshooting, and performance optimization in high-temperature environments are all essential practices to maximize their lifespan and efficiency.

By following the guidelines outlined in this article—covering installation techniques, maintenance routines, replacement procedures, troubleshooting methods, and high-temperature optimization—operators and technicians can prevent unexpected downtime, reduce repair costs, and maintain consistent production quality.

Key recommendations include:

In conclusion, understanding and managing Barmag bearings effectively allows textile machinery operators to enhance operational efficiency, prolong equipment life, and achieve reliable performance under a wide range of conditions. Proper attention to these bearings is not only a preventive measure but a key factor in maintaining smooth and uninterrupted textile production.

Barmag bearings are essential for ensuring smooth operation, reducing friction, and maintaining reliability in textile machinery. Proper installation, maintenance, and performance optimization allow these bearings to operate efficiently even under high-speed or high-temperature conditions. At Jiaxing Shengbang Mechanical Equipment Co., Ltd., we leverage our advanced equipment for production, inspection, and testing of spinning machinery, including temperature calibration for hot godet from Barmag, ensuring that all bearings used in our machines meet the highest performance standards.

Regular maintenance, timely troubleshooting, and careful installation are critical. This includes proper lubrication, alignment checks, temperature monitoring, and replacement when signs of wear appear. At Jiaxing Shengbang Mechanical Equipment Co., Ltd., our R&D Department, Production Department, and advanced CNC and plasma-coating equipment support the development and maintenance of bearings and spinning machinery, allowing customers to achieve reliable and long-lasting performance.

Yes. Jiaxing Shengbang Mechanical Equipment Co., Ltd. is a comprehensive technological company specializing in the development, production, sales, and maintenance of key parts and spinning machines. We also provide an R&D lab and a yarn spinning lab where customers can conduct spinning tests themselves. With our advanced technology, equipment, and branches in Shanghai and Nantong, as well as cooperation with Shanghai Panguhai Technology Engineering Co., Ltd. and Haian Jingtong New Material Technology Co., Ltd., we offer both technical support and hands-on testing opportunities to ensure optimal use of Barmag bearings and other machinery components.