In the dynamic realm of the textile industry, TMT Spinning Machine Parts play a crucial role in ensuring the smooth operation and efficiency of spinning machines. These parts are the unsung heroes that contribute to the production of high - quality yarn, driving the industry forward with their innovative designs and reliable performance.

TMT Spinning Machine Parts are crafted using state - of - the - art manufacturing techniques. Precision machining processes are employed to create components with exacting tolerances. This precision is essential as even the slightest deviation can impact the performance of the entire spinning machine. Computer - controlled machinery is often utilized to cut, shape, and assemble parts with utmost accuracy. For example, parts such as rollers and spindles are manufactured to precise dimensions, ensuring seamless interaction within the spinning machine and minimizing friction.

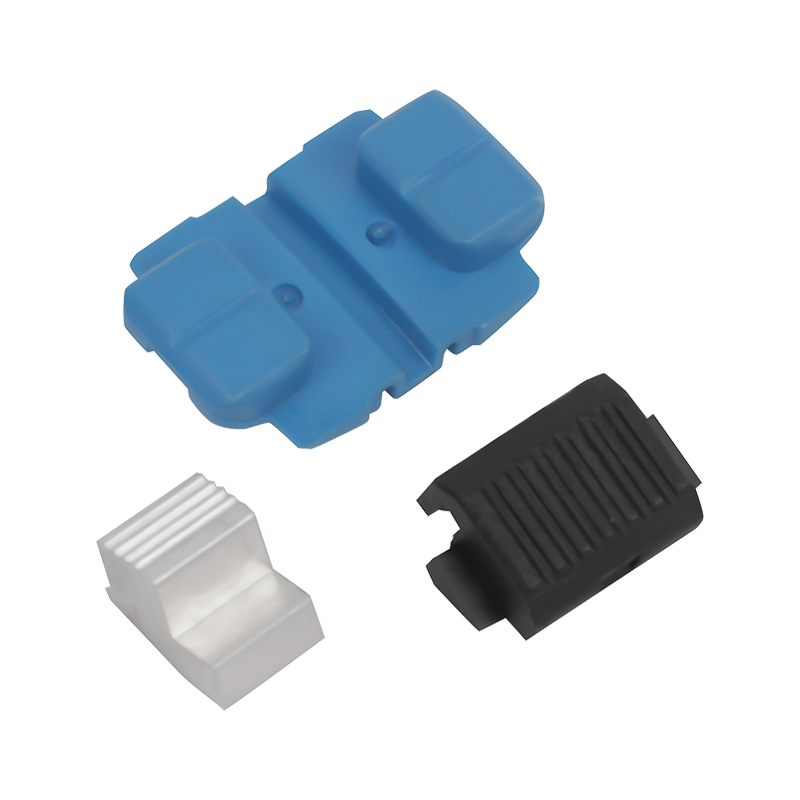

The choice of materials for TMT Spinning Machine Parts is of utmost importance. Durable metals, high - strength polymers, and specialized alloys are commonly used. Metals like stainless steel and aluminum are favored for their strength, corrosion resistance, and lightweight properties. High - strength polymers are used in components where reducing weight without sacrificing durability is key. These carefully selected materials enhance the longevity and performance of the parts, allowing them to withstand the rigors of continuous operation in textile manufacturing plants.

TMT Spinning Machine Parts are designed to optimize the spinning process. Components such as drafting rollers and aprons work in harmony to control the fiber flow, ensuring uniform drafting and consistent yarn quality. The use of advanced spindle designs reduces vibration and noise, enabling the machine to operate at higher speeds while maintaining stability. This not only increases the production output but also improves the overall efficiency of the spinning mill.

These parts are adaptable to different types of yarn production. Whether it's the production of cotton, synthetic, or blended yarns, TMT Spinning Machine Parts can be customized to meet specific requirements. For instance, different types of carding elements can be used to process various fiber lengths and qualities, allowing textile manufacturers to produce a wide range of yarns for different end - use applications, from apparel to home textiles.

With the continuous growth of the global textile industry, the demand for TMT Spinning Machine Parts is on the rise. As textile manufacturers strive to increase production capacity and improve product quality, they are investing in high - performance spinning machines and, consequently, in quality parts. The expansion of emerging textile markets, especially in Asia and Africa, is further fueling this demand.

The future of TMT Spinning Machine Parts is likely to be shaped by technological advancements. We can expect to see the integration of smart sensors and IoT (Internet of Things) technology into parts. These sensors will be able to monitor the performance of parts in real - time, providing valuable data on wear and tear, temperature, and vibration. This data can be used to predict maintenance needs, reducing downtime and increasing the lifespan of the parts. Additionally, the development of more sustainable materials and manufacturing processes will also be a key focus, aligning with the growing global emphasis on environmental responsibility in the textile industry.