The evolution of textile manufacturing processes has led to innovations that significantly enhance efficiency and quality, with one of the key advancements being the POY (Partially Oriented Yarn) spinning production line. This technological development has transformed how yarn is produced, making the process faster, more cost-effective, and flexible.

A POY spinning production line is an essential part of the modern yarn production process, particularly in the manufacture of filament yarns. POY is the initial product created during the production of fully drawn yarn (FDY). The POY spinning process involves drawing a fiber under controlled tension to partially orient the polymer molecules, making it suitable for further processing into more refined yarns, such as FDY or textured yarns.

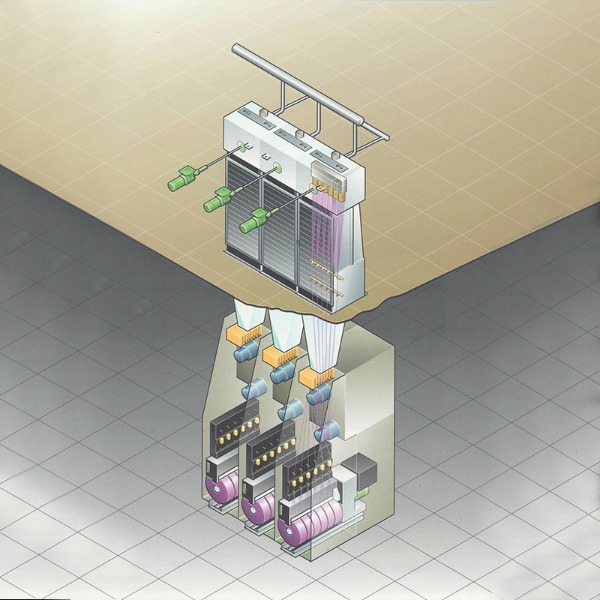

The POY spinning production line consists of several key steps that work in tandem to produce high-quality POY with consistent properties. These steps include fiber preparation, spinning, drawing, cooling, and winding, all of which are tightly controlled to ensure uniformity and efficiency.

One of the first and most important steps in the POY spinning production line is fiber preparation. The raw material, typically polyester, nylon, or polypropylene, is first melted and extruded into filaments. The preparation phase plays a vital role in ensuring that the fibers are uniformly processed before spinning, which directly impacts the efficiency of the entire production line.

Key Advantages:

The spinning process is where the polymer fibers are extruded through spinnerets to form continuous filaments. These filaments are then subjected to the drawing process, where they are stretched under controlled tension. The POY spinning production line is equipped with advanced drawing mechanisms that maintain a constant draw ratio to ensure consistent yarn thickness and strength.

Key Advantages:

The temperature of the yarn during the spinning process is crucial for maintaining its integrity and quality. The POY spinning production line integrates advanced cooling systems to regulate temperature, ensuring that the yarn does not lose its shape or quality during the spinning and drawing processes.

Key Advantages:

Once the yarn is fully drawn, it is wound onto bobbins or packages for further processing. The winding system in the POY spinning production line is designed to handle high speeds without compromising the quality of the yarn. The efficiency of the winding process contributes directly to overall productivity, ensuring that large quantities of POY are produced in minimal time.

Key Advantages:

The use of a POY spinning production line offers several advantages that directly improve efficiency and product quality:

The primary benefit of a POY spinning production line is its ability to operate at high speeds. Automation, precise control over drawing ratios, and temperature regulation allow manufacturers to produce POY faster than ever before. The result is a significant increase in output and a reduction in production time, which translates to lower operating costs.

Because the process is automated and optimized, POY spinning production lines help reduce labor costs and material wastage. With precise control over fiber preparation, spinning, and drawing, manufacturers can achieve greater consistency, minimizing defects and increasing yield.

A POY spinning production line is highly versatile and can handle a variety of raw materials, including different types of polymers and fibers. This versatility enables manufacturers to produce a range of yarns, from basic POY to more advanced FDY and textured yarns, with minimal changes to the production line setup.

With tightly controlled processes and advanced machinery, the POY spinning production line ensures a high-quality finished product. The yarn produced is stronger, more consistent, and ready for further processing into final products such as fabrics and textiles.

Jiaxing Shengbang Mechanical Equipment Co., Ltd. is a leading company that specializes in the development, production, and maintenance of spinning machinery, including POY spinning production lines. The company’s state-of-the-art production facilities and expertise in spinning technologies have enabled them to create efficient, high-performance POY spinning lines that meet the needs of modern textile manufacturers.

Jiaxing Shengbang offers a comprehensive range of services, including the design and production of key spinning parts, maintenance of spinning machines, and R&D of new materials. The company’s advanced equipment, such as CNC machine tools and plasma-coating systems, ensures that the POY spinning production lines are optimized for maximum performance.

| Feature | Description |

|---|---|

| High-Speed Spinning | Enables fast yarn production, improving output. |

| Temperature Control | Ensures yarn quality is maintained throughout the process. |

| Automated Drawing Mechanism | Consistent fiber stretching for uniform yarn quality. |

| Efficient Winding | Automated winding system for faster packaging. |

| Versatility | Capable of handling various raw materials and producing multiple types of yarn. |

| Precision Fiber Preparation | Reduces material waste and ensures uniformity in the final product. |

In conclusion, the POY spinning production line plays a pivotal role in improving efficiency in yarn production. With advancements in spinning technology, manufacturers can achieve higher production speeds, lower costs, and better-quality yarns. Through the integration of automation, precision control, and cutting-edge mechanical equipment, the equipment provided by Jiaxing Shengbang Mechanical Equipment Co., Ltd. ensures that the POY spinning process remains at the forefront of yarn production technology.

Q1: What are the key benefits of using a POY spinning production line in yarn manufacturing?

A1: The key benefits include higher production speeds, reduced material wastage, lower labor costs, and improved yarn quality.

Q2: Can a POY spinning production line handle different types of fibers?

A2: Yes, the POY spinning production line is highly versatile and can process various raw materials, including polyester, nylon, and polypropylene.

Q3: How does temperature control impact the efficiency of POY spinning?

A3: Temperature control ensures that the yarn maintains its shape and quality throughout the spinning and drawing process, preventing defects and reducing the need for rework.

Q4: How does a POY spinning production line improve product consistency?

A4: The precise control over the drawing ratio, fiber preparation, and cooling process ensures that the yarn produced is consistent in terms of strength, thickness, and quality.